Precision Alignment for Optimal Engine Performance

At ATP Engines, we understand the critical importance of precise alignment in engine components. Our line boring services are designed to restore and ensure the perfect alignment of main bearing and camshaft bores, which is essential for the smooth operation and longevity of your engine.

What is Line Boring?

Line boring, also known as align boring, is a machining process that corrects the alignment and size of bores within engine blocks. Over time, factors such as wear, overheating, or component failure can cause these bores to become misaligned or distorted. This misalignment can lead to increased friction, premature wear, and potential engine failure. Our line boring process re-establishes the correct centerline alignment, ensuring that components like the crankshaft and camshaft operate seamlessly.

Our Line Boring Capabilities

- Main Bearing Bore Alignment:

Restoring the alignment and diameter of main bearing bores to OEM specifications. - Camshaft Bore Correction:

Ensuring camshaft bores are perfectly aligned for optimal valve timing and engine efficiency. - Custom Applications:

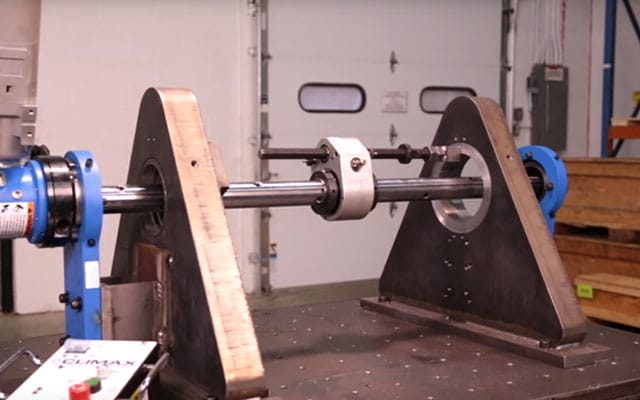

Handling a wide range of engine types, from small automotive engines to medium-range diesel engines. - State-of-the-Art Equipment:

Utilizing advanced line boring machines and precision measurement tools to achieve exact tolerances.

Why Choose ATP Engines for Line Boring?

- Expert Technicians:

Our team has extensive experience in engine remanufacturing and understands the nuances of various engine designs. - Quality Assurance:

Post-machining inspections ensure that all bores meet strict quality standards. - Comprehensive Services:

Beyond line boring, we offer a full suite of engine remanufacturing services, providing a one-stop solution for your engine needs.

When is Line Boring Necessary?

Consider line boring if:

- You’ve experienced a crankshaft or camshaft failure.

- There are signs of uneven wear or scoring in the bearing bores.

- You’re rebuilding an engine and want to ensure all components are aligned to factory specifications.